Seal Test / Sealing Test inc|seal testing methods pdf : dealer Explore FasTest's custom engineered solutions, designed to meet unique .

Play for free BBQ Steak Tacos on Capy.com! BBQ Steak Tac.

{plog:ftitle_list}

WEB28 de jun. de 2021 · Die Einsätze, die direkt auf der Null landen, gewinnen mit einer Quote von 1:36. Pickt ihr euch zwei Zahlen heraus, unter denen eine Null ist, habt ihr euch eine 1:18-Quote gesichert. Bei drei Zahlen .

seal testing techniques pdf

lg velvet drop test

seal testing techniques

Connect with FasTest for all of your sealing connection needs. Explore FasTest's top-quality quick connectors and couplings, engineered for reliability.Hand-Operated Connectors - FasTest IncAutomotive - FasTest Inc

Discover FasTest Inc's range of quick connect tools for various industries, .The CoreMax® access valve system provides up to five times greater .Explore FasTest's custom engineered solutions, designed to meet unique .

Accessories - FasTest IncReduce testing variation with a complete package of FasTest Sealing Connection .

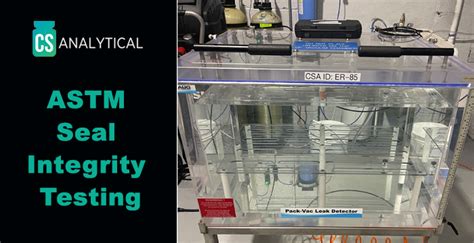

lg x power drop test

Enter your FasTest® part number or select your FasTest® connector details to find .FasTest is a dedicated manufacturer of advanced engineered Sealing .Seal strength test methods evaluate the integrity of seals on various types of packaging, from food containers to medical supplies. These tests measure the force required to separate .FlexPak’s diverse seal integrity tests can ensure your packages meet the required ASTM testing standards in your industry, with the ability to test a variety of product and packaging types. Our .

PTFE Teflon Rotary Lip Seals. Performance Sealing Inc designs and manufactures a full line of rotary lip sealing solutions for your application. PSI Seal combines material technology and seal design to optimize your sealing performance. . joint test program to develop the right sealing solution that improves your products sealing performance. .Policy: Inspect and test any heat-sealing device with the pouch integrity test to ensure proper seal of peel pouch sterile barrier systems and test self-sealing pouches. The pouch integrity tests will be conducted every day that a heat-sealing device is used for paper/poly and Tyvek®/poly pouches with a push indicator dye test. This test is to . Mechanical Research & Design, Inc. has been providing innovative and proven Pipe Plugs all over the world for nearly 25 years. Also called pressure test plugs, pipe stoppers, pipe bungs, line stops, or inline .

Providing battery sealing solutions and ways to test the seal on and off the production line. We’ve invented a new method for sealing e-fill port holes that can increase production by as much as 10% compared to a standard crimp or laser-welded plug.

Sealing Connection Tool and test part should be rigidly fixtured to prevent separation when under pressure (fixture not required for vacuum applications). ACTUATION METHOD: Pneumatic: . *ncludes seals(s) and metal parts for one complete seal set. Neoprene® seals are standard. I

During those years, he has had the opportunity to manage and/or play a key role in seal and bearing testing, test method development, final validation, defining root case analysis of failure modes and developing training materials. . Mr. Sitko has been with Trelleborg Sealing Solutions in a variety of engineering positions for the last 13 .

Instructions for Use: Pouch Seal Integrity Test Brand Name of Product Pouch Seal Integrity Test Generic Name of Product Pouch Seal Integrity Test Product Code Number(s) PS-001, TPS-001 Intended Use To test the integrity of the seals for heat seal and self-seal pouches. Range of Applications for Product Testing the sealing process for both paper/poly and .

Seal internally to a wide variety of smooth or threaded tubes. Uniform sealing for a leak tight connection, even into threaded, rough and oily surfaces. Ideal for automated processes and high volume production testing; ICON™ | Intelligent Connection Technology3.1.9 hot tack, n—strength of a hot seal measured at a specified time interval after completion of the sealing cycle but prior to the temperature of the seal reaching ambient. 3.1.10 hot-tack curve, n—a plot of hot-tack strength versus sealing temperature (see Fig. 3). FIG. 1 Test Strip Failure Modes F 1921 – 98 (2004) 2Twist ’N Seal® Pipe Sealing Plug Product Description and Features. Securely block off a variety of pipes from the inside with the Test-Tite Twist ‘N Seal Pipe Seal Kit. Quick and easy to use, this pipe seal kit allows you to install a temporary sealing plug inside DWV (drain, waste, and vent) pipe, stopping the water flow while you solder .There are two common methods for sealing glass ampules; the “Tip Seal Method” and the “Pull Seal Method.” This paper explains the differences, benefits, and constraints of using each method. . tubes, test tubes, and chilled ampules. The Ampulmatic-10 System was designed to be easily adjusted for different ampules sizes and liquids. .

Dedicated TestBed (DTB) for detecting the sealing performance of Metal Rubber (MR) was designed and manufactured based on Siemens S7-200 PLC. The experiments, such as high temperature and large temperature difference experiment, could be conducted with real-time monitoring by DTB. The general design including mechanical and control part of DTB is .

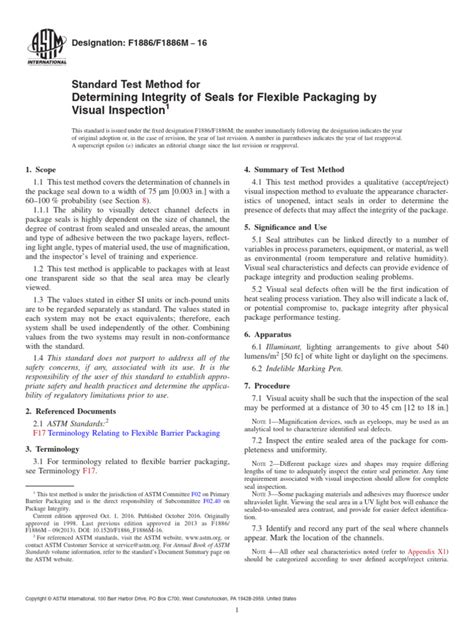

The easiest to do is hot water seal. Use distilled or demineralised water with a conductivity below 150 microsiemens and a pH of about 6 (5.5-6.5 is not uncommon). . The sealing test is also described by BS EN 12373-6. I don't know if it is exactly the same as the ASTM, I haven't carried out any gap analysis to find out.5.1 Test Method F88 has been the standard for the mechani-cal peel strength testing of peelable seals since the 1960s. Normally the testing is run on a portion of the seal. The result is an actual seal strength picture of that portion of the seal.This test method is different in that the entire package seal is peeledOur comprehensive seal testing services are designed to evaluate and validate the performance of your sealing solutions. We employ a range of rigorous testing methods to simulate real-world conditions, identifying potential issues and verifying that your seals meet all .

If your house qualifies, you might be able to get a complete home air sealing package (including duct sealing and insulation upgrades) for ZERO money upfront. Get whole-house air and duct sealing—for NO upfront cost. Yes, .Various criteria such as the force required and the chamfering of the sealed seam are evaluated. Alongside the seal check, the ink test and the seal seam strength test, the peel test is a common method for assessing the seal seam quality of a sealing device. Performing the peel test makes it possible to detect and rectify faulty seals in good time.

For this reason, the test is a poor indicator of seal function at low temperatures. . (ASTM D1329) is currently the most reliable test for low-temperature sealing performance. A rubber seal is .

The drill tail of a rock drill meets high-frequency fretting in both the rotational and axial axes. The pure water seal is prone to damage and failure owing to its difficult working features and the low viscosity of the water medium. Orthogonal testing is used to simulate and model the Y-shaped seal ring to enhance the performance of the water seal. The maximum .

This specification details a test method for static O-ring seals in elastomeric materials which are subject to pressurized gas media at low temperatures. It gives guidance on the design of test equipment, standard test parameters, and reporting criteria.

ASTM-F1921 Standard Test Methods for Hot Seal Strength (Hot Tack) of Thermoplastic Polymers and Blends Comprising the Sealing Surfaces of . An additional prerequisite is that the operator shall have no influence on the test after the sealing sequence has begun. These test methods do not cover non-instrumented manual procedures employing .Another tip to to getting a seal on the noble 4 is trying the Etymotic recommended way of inserting an IEM. Relax your jaw and pinch the top part of your earlobe up. Insert the IEM then close your jaw and let go of your earlobe or vice versa.It follows the principles of ASTM F1921 Standard Test Method for Hot Seal Strength (Hot Tack) of Thermoplastic Polymers and blends comprising the sealing surfaces of flexible webs. HT-2PC Auto Heat Seal and Hot Tack Tester quantity. Add to Enquiry.

Test Method 1014 seal test requires gross leak testing to occur within one hour of sealed packages’ removal from the helium bombing process. Per Figure 5, gross leakers are identified in multiple ways, including . When sealing processes resulted in seals with leak rates in the E-10 air leak rates with low standard deviations, no gross .As a result in the late 1960's the first iteration of Mil-STD-883 Test Method 1014 (Seal) was released 2. The proposed hermeticity test was required, and still . Hermetic Sealing Per the Mil specs epoxies or other polymeric materials cannot be used to create or improve a hermetic seal, moisture will eventually penetrate through the .Test Results: K-Seal® has successfully completed 2 entire test sequences in succession in accordance with test methods set out in ASTM D3147. See Tables 1 and 2 below for the final test results. Table 1 – K-Seal® ASTM D3147 final leak test results 2 A ASTM terminology for describing quality of seal formed. The term “Sealed”in ASTM D3147Seal Quality Tests USP <1207.3>: “Package seal quality tests” are checks used to characterize and monitor the quality and consistency of a seal parameter related to the package seal, providing some assurance of the package’s ability to remain integral Quality tests ensure that seal attributes, package materials,

Resultado da Jogo da Corrupção - Temporada 1. Data de lançamento 2022-11-04. Séries : Jogo da Corrupção. Com Albano Jerónimo , Eduardo Moscovis , Maria Fernanda Cândido , .

Seal Test / Sealing Test inc|seal testing methods pdf